Ecological evaluation of the material concepts and production procedures as well as end-of-life and new-life scenarios for (bio) hybrid materials

The objective of this project is the development of suitable respective recycling and disposal concepts for the materials and material combinations produced within the scope of the Fraunhofer Project Center in Wolfsburg, whilst simultaneously already taking the recycling aspect into account during the selection of the materials and the manufacturing processes.

For the innovative materials and combinations developed at the Project Center Wolfsburg, neither recycling scenarios nor an ecological evaluation have so far existed. In order to ensure the sustainable application of these materials, the economic and ecological assessment of their entire lifecycle, in particular with regard to possible utilization scenarios, is urgently necessary.

In addition to the development of appropriate end-of-life and new-life concepts for the manufactured components as well as for the material residues accrued during the process, the ecological and economic evaluation of the starting materials, material combinations and production processes is being undertaken.

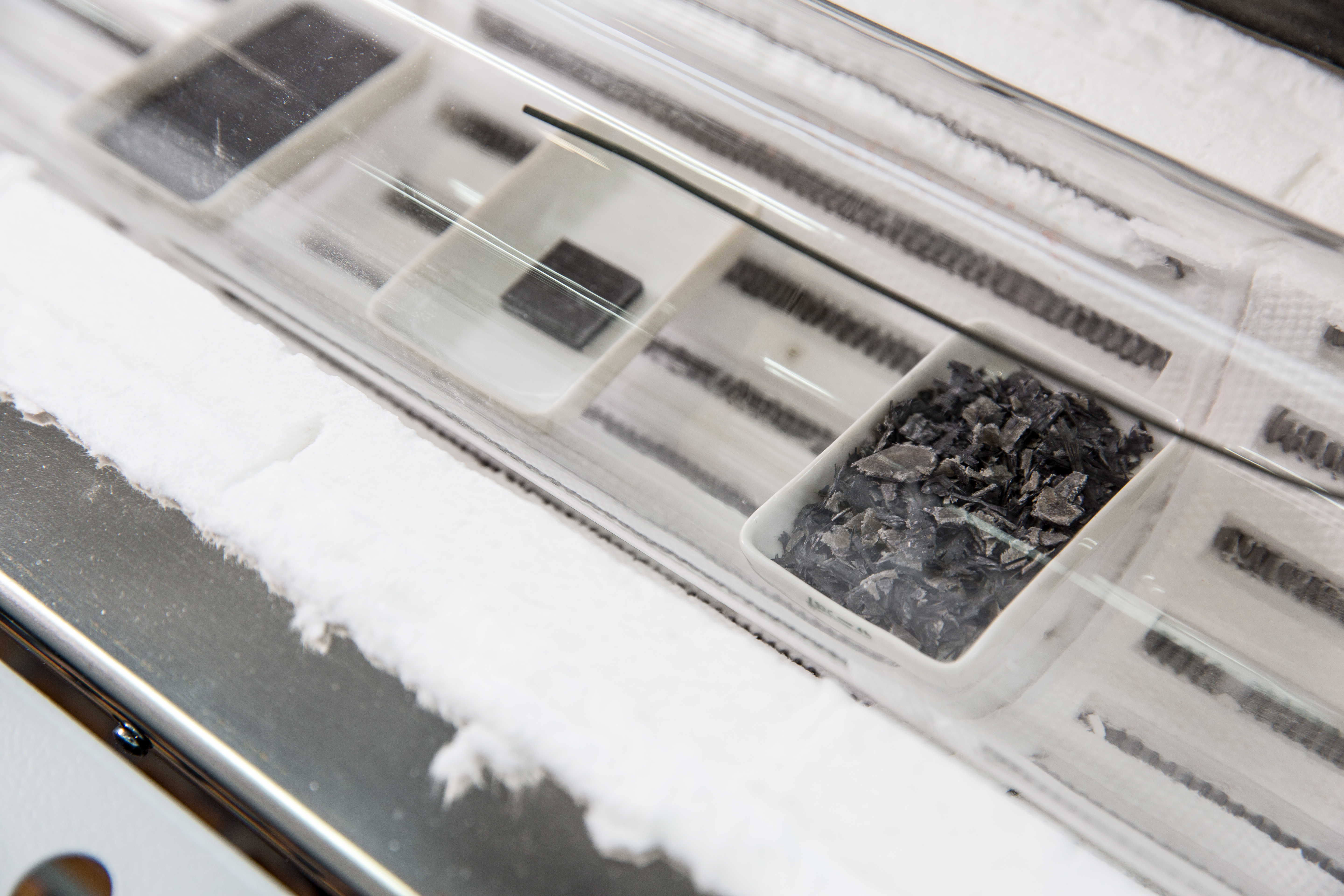

In order to achieve these goals, we initially identify the most important materials and material combinations being utilized. For this, we develop end-of-life and new-life scenarios, taking into account during the preliminary stages the steps which are hereby necessary, such as dismantling. The possible recycling procedures include mechanical, chemical and thermal processes. The combination of different methods, for example mechanical recycling with pyrolysis, is also possible.

Following completion of these process steps, we also investigate the application possibilities and areas of utilization for recycled fibers, composites and residual materials. The recycling procedures can hereby be further optimized in order to increase the range of application possibilities for the recyclates and, for example, to optimize particular aspects, such as the energetic and economic outlay for the processes.

Finally, we consider the lifecycle of the materials - from the raw starting material through the process itself and on to recycling. The results achieved during the duration of the project flow directly into the respective ongoing parallel projects at the Project Center, with the effect that the recycling aspect can be incorporated as early as during the selection of the materials and processes.

Fraunhofer Project Center Wolfsburg

Fraunhofer Project Center Wolfsburg