Plasma surface functionalization of fibres and semi-finished fibre products

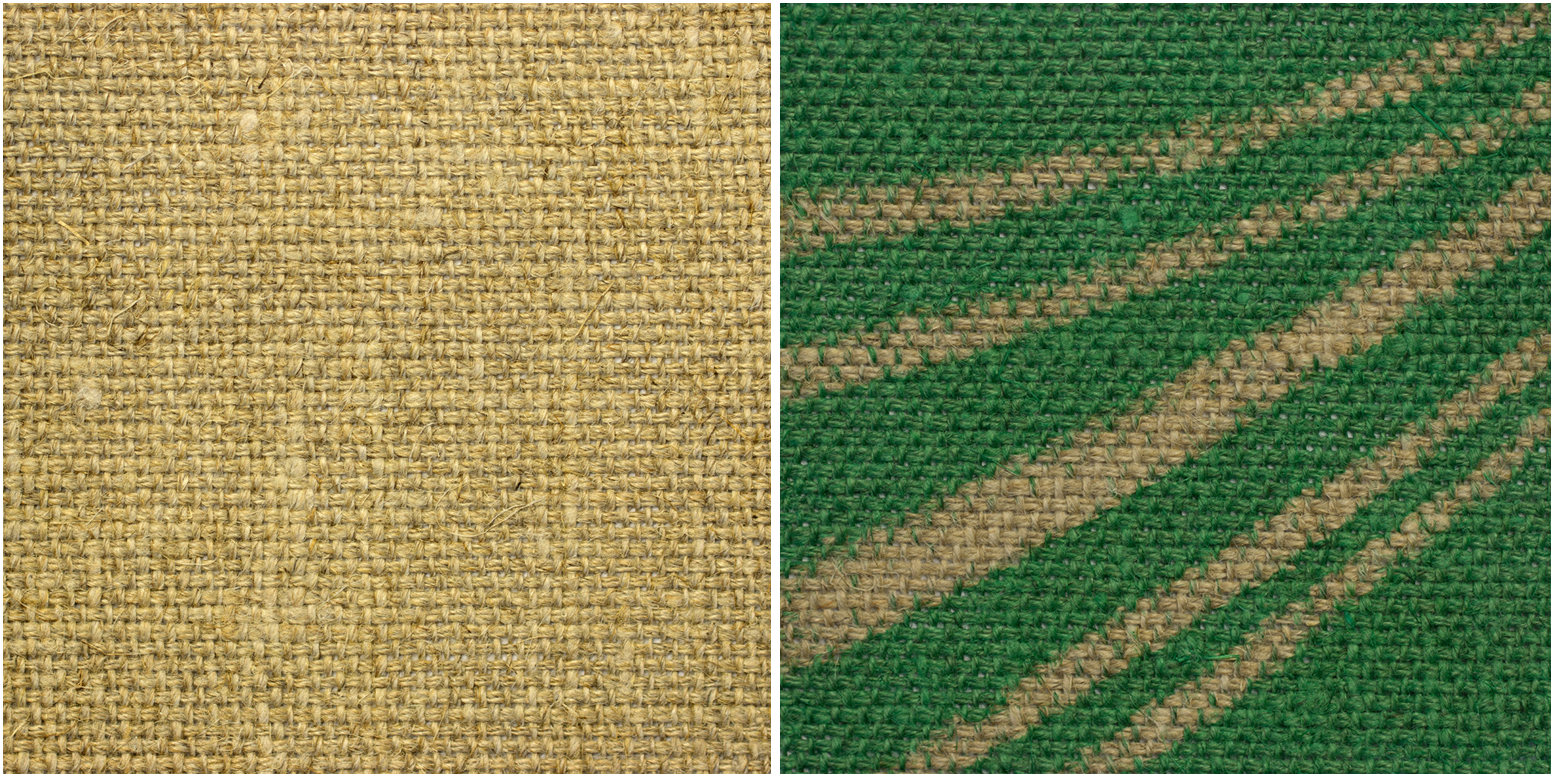

In the project "Oberhalb" fibres and semi-finished fibre products are treated by means of atmospheric pressure plasma sources for a cost-efficient and need-based improvement of their wettability and infiltration. This enables considerably shorter production cycles and better mechanical properties of the resulting fibre-reinforced polymers (FRPs).

Untreated fibres and semi-finished fibre products often show a low wettability and poor impregnation with many polymer matrix systems. Therefore, the fibre materials are usually sized in order to promote their adhesion to the matrix. However, the liquid sizing chemicals have to be customized to the used polymer matrix and require subsequent time- and cost-consuming process steps concerning the fibre drying and a proper utilisation of the chemicals.

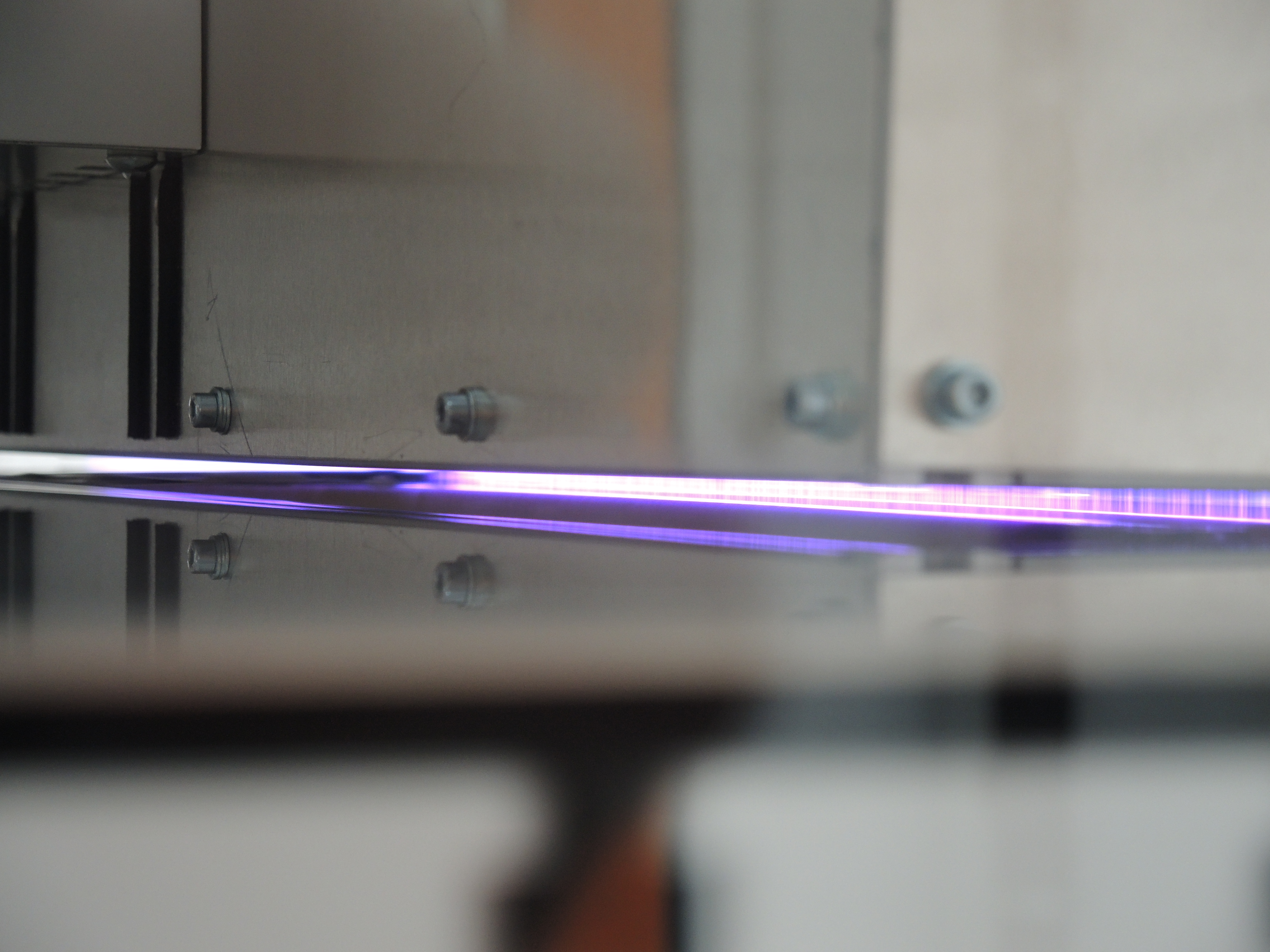

Atmospheric pressure plasma processing offers an alternative dry and environmentally friendly physical technique for a cost-efficient and need-based fibre pretreatment in industry. Thereby, the fibre surface can be gently cleaned and additionally activated due to the incorporation of polar, oxygen containing functional groups. This leads to a considerably improved wettability of the fibres with polymer matrix systems and promotes the adhesion formation between the two components.

In this project the plasma treatment of different types of fibres (natural, polymer, glas and carbon fibres) is carried out at atmospheric pressure. This allows compact systems that can be easily automised and integrated into processing chains if required.

Fraunhofer Project Center Wolfsburg

Fraunhofer Project Center Wolfsburg