Thermal management for battery systems in electric vehicles

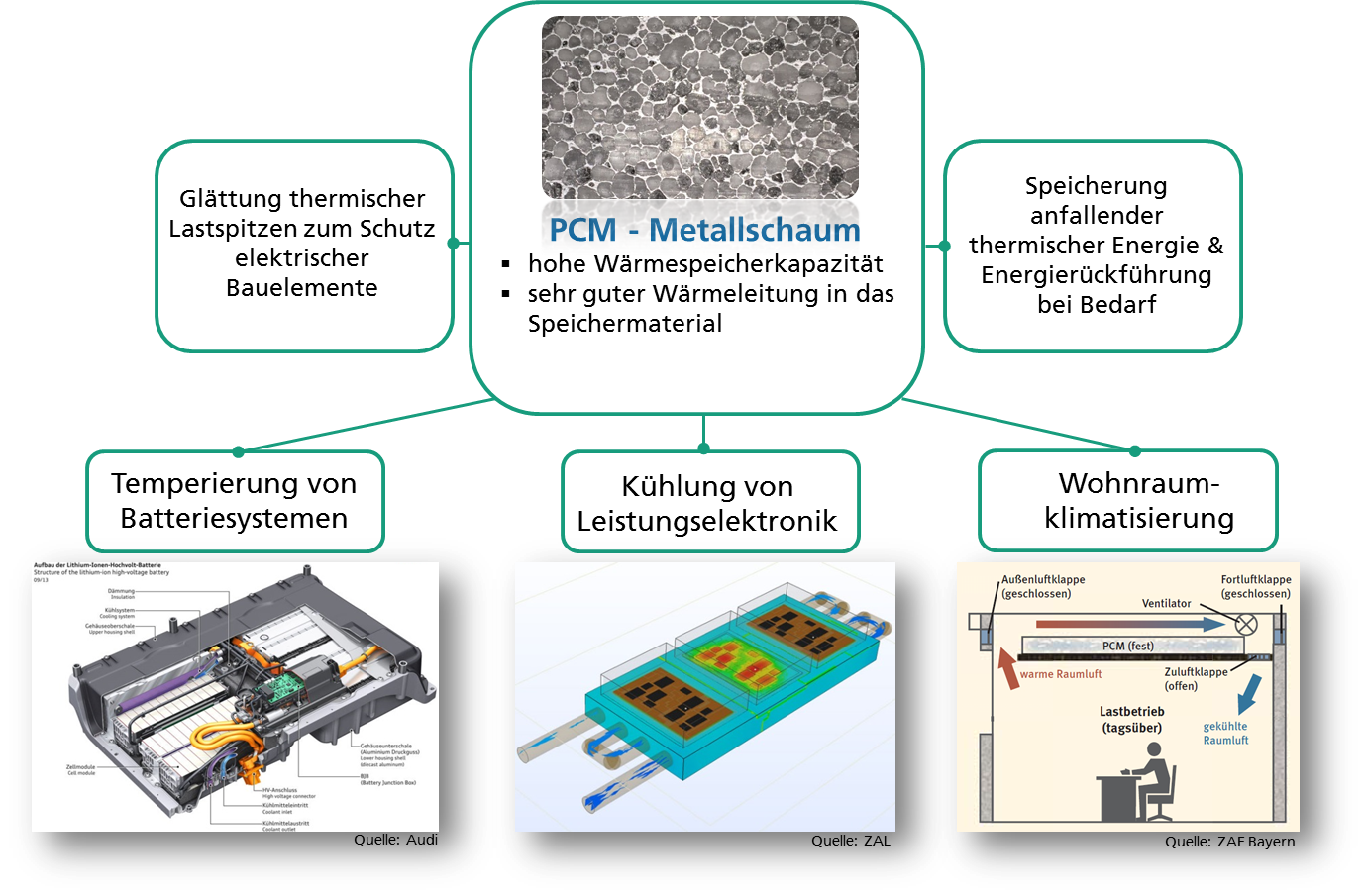

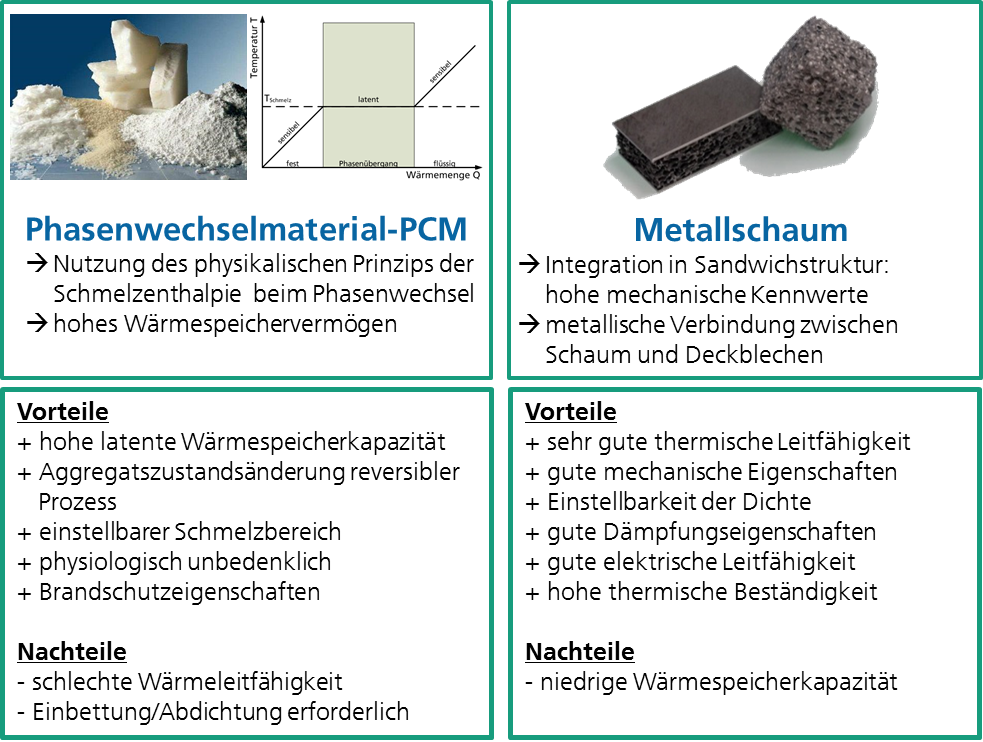

To increase the range of electric vehicles and to protect the battery system from thermal overload, a passive thermal management is to be developed. This is achieved by combining metal foam with phase change material, a compound with application-specific adjustable thermal and mechanical properties.

Batteries generate a power loss due to their internal electrical resistance during operation, that is both in terms of energy dissipation and energy consumption. The power loss is reflected in a heating of the respective battery cells. The magnitude of the power loss depends on a number of factors: size of load, cell structure, operating temperature and others. In any case, excessive heating of the battery cells has a negative effect on their performance and durability. Active cooling means an additional energy expenditure, which would likewise have to be achieved by the battery cells in an electric vehicle.

At present, batteries are the limiting factor in electric vehicles; i. e. the performance of the battery cells determines the driving performance and, above all, the range of the vehicles. Any additional load beyond the vehicle propulsion is therefore relevant for the range.

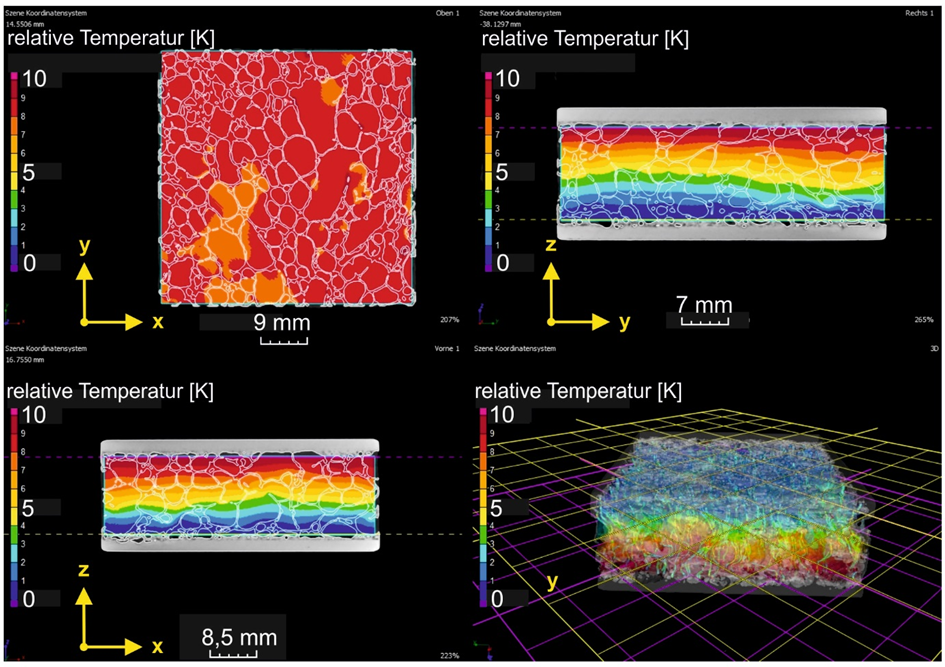

The project aims to develop a passive cooling system that does not require additional energy. The infiltration of closed-cell aluminium foam with phase change material (PCM) is particularly innovative. PCM make the physical principle of melting enthalpy usable during phase transition solid-liquid. The phase transition is reversible and defined to a narrow temperature range. Depending on the direction of the phase transition, energy can be absorbed or emitted by the material.

In this case, the aluminium foam serves as a carrier material for the PCM and guarantees heat conduction to the PCM. In addition to the functions of intrusion protection and energy absorption in the event of a crash, the aluminium foam core can also be used for smoothing thermal load peaks and buffering excess heat.

Fraunhofer Project Center Wolfsburg

Fraunhofer Project Center Wolfsburg