Secure Applications for Electric Battery Housing

In a two years long international research project the companies Havel metal foam (HMF), FiberCheck and the research partner Fraunhofer Institute for Machine Tools and Forming Technology (IWU) – as a member of the Fraunhofer Project Center Wolfsburg – want to develop, together with their Swedish partners RISE SICOMP and AP&T, a battery case that ensures a higher safety and can be produced in a shorter and more economic process than actual solutions.

Functional integration and lightweight design are important tasks especially for modern electric vehicles. Development of multi-functional assemblies for the battery box of the future is one of the challenges in the electric mobility.

The housing must perform many tasks: structural stiffening and sealing (waterproofness) as well as crash protection and thermal management for the batteries. The goal of the project is to develop a multifunctional lightweight battery housing based on these requirements. An effort on development and validation of suitable manufacturing technology for efficient production will be done.

The battery frame should be designed so stiff that it protects the battery against of penetrating parts (vehicle parts, stones, etc.), in the event of a crash, as well as protecting the battery cells against intrusion. The thermal management function is integrated in the foam. Additionally, sensors for structural health monitoring are planned to be integrated.

Joining of Swedish and German knowhow in electric mobility applications, lightweight design and process technology will lead to an innovative lightweight multifunctional battery housing.

Main focuses of the project:

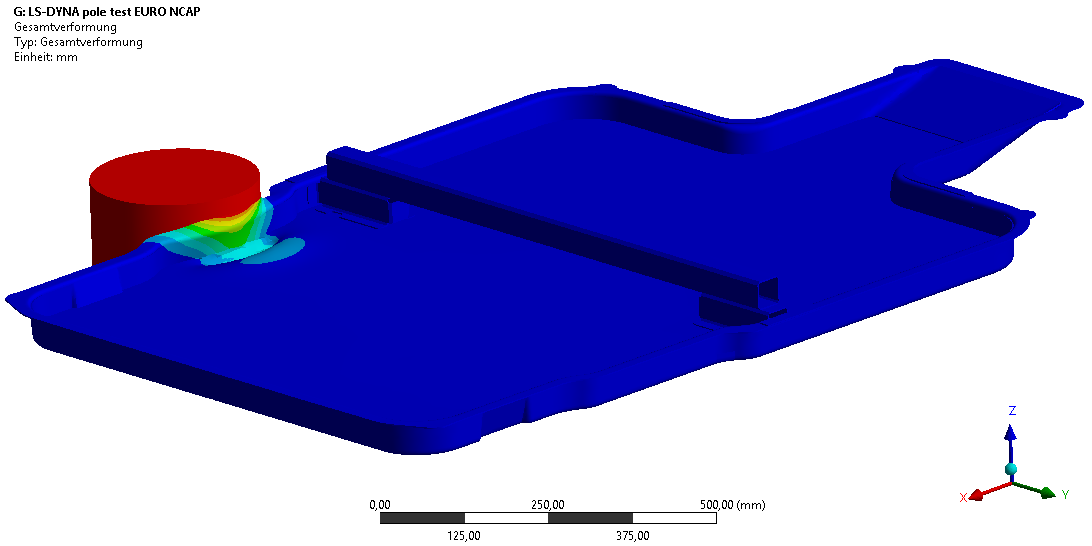

- Construction and design of a lightweight battery housing with a focus on safety requirements (bollard test)

- Development of an advanced material models for metal foam phase change material (PCM) composite

- Intrusion protection by the use of metal foam and profiles

- Integration of sensors for monitoring the battery housing (moisture measurement, temperature, expansion)

- Process development and testing for an SMC metal hybrid battery housing

- Production of a battery case on a scale of 1: 1

- Structural and thermal test of the battery case

Duration: 15th June 2020 - 14th June 2022

Partners:

Fraunhofer Project Center Wolfsburg

Fraunhofer Project Center Wolfsburg