Process and tool technologies for functionally integrated hybrid construction methods

The focus of the research campus project "Process and tool technologies for functionally integrated hybrid designs (TechnoHyb)" is the development and application of process and tool technologies for functionally integrated hybrid components in a large-scale vehicle production.

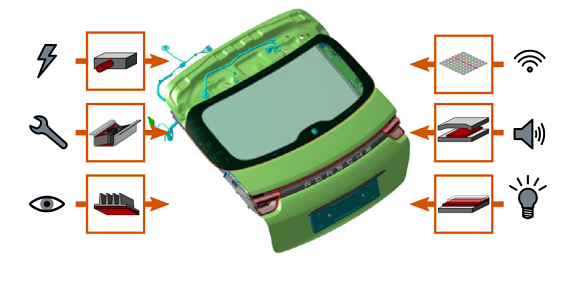

By combining materials with different properties, hybrid construction offers great potential for integrating non-structural functions into structural components.

Depending on the chosen integration strategy, a wide range of potentials is offered, such as a reduction in weight, costs or assembly processes. Functional integration can thus make a major contribution to the widespread use of hybrid construction.

However, these are faced with numerous challenges. For example, functionality, reparability and recyclability must still be fully ensured. In addition, it must be possible to implement the components in series production processes in order to achieve widespread use. In this context, it is particularly important to consider the influences of function integration on the respective manufacturing processes and the tool, as well as the reverse influences.

The overall goal of the research campus project "TechnoHyb" is the development of economical, function-integrated body systems in hybrid design. In this context, tooling and process technologies are to be developed that ensure the implementation of functionally integrated hybrid components even under the constraints of large-scale production.

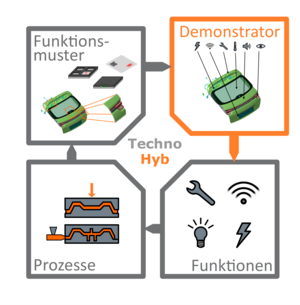

For this purpose, approaches for function integration are analyzed and selected with regard to their manufacturability and effects on the tool. The feasibility will be investigated step by step from a test specimen to a functional sample (sections of the final component) to the demonstrator level (entire component).

The knowledge gained in this way can also be transferred from the vehicle tailgate considered within the project to other applications. In addition, various tools are being developed to support the development of function-integrated components.

As a member of the Fraunhofer Project Center Wolfsburg and project partner of the research campus project "TechnoHyb", the Fraunhofer IWU is responsible for the technology development and the production of the function-integrated demonstrators in the project consortium. From the initial concepts for integrating acoustic, electronic and structural functions, through preliminary tests and functional prototypes, to the production of the scaled trunk lid, the IWU is contributing its expertise in the field of economic and ecological lightweight construction.

For more information click here (in German)

Duration: 2020 – 2024

Project partners: Fraunhofer IWU, Technische Universität Braunschweig, Institut für Konstruktionstechnik (IK), INVENT GmbH, C-Con GmbH, Porsche AG, VOLKSWAGEN AG

The research campus project "TechnoHyb" is funded by the Federal Ministry of Education and Research.

Fraunhofer Project Center Wolfsburg

Fraunhofer Project Center Wolfsburg