Overview

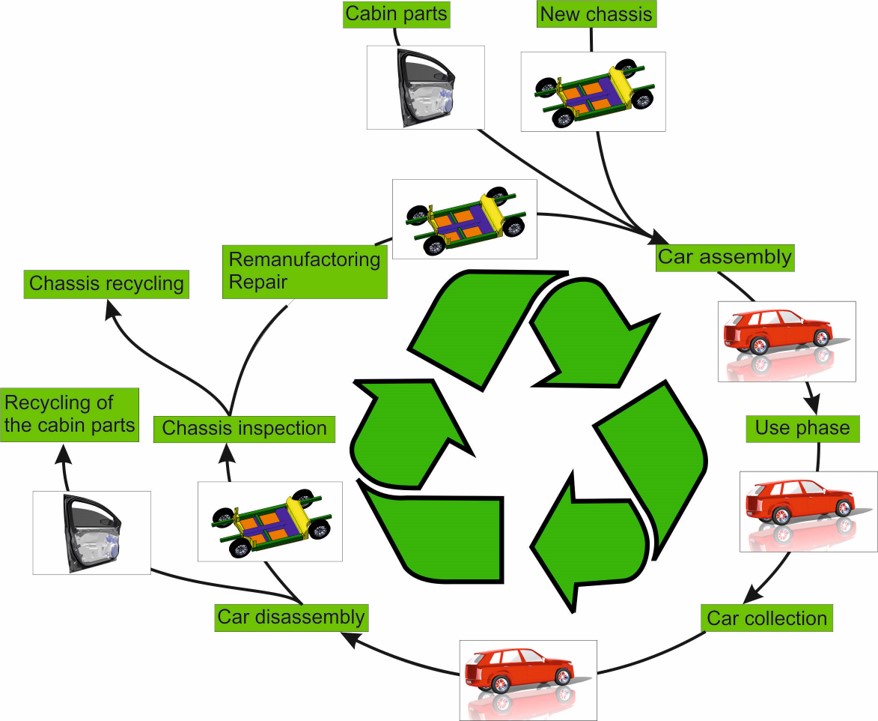

Due to the depletion of fossil resources, the use and development of sustainable materials and processes as well as the recovery of raw materials from End-of-Life (EoL) products and components is a central component in order to meet the long-term needs of future generations.

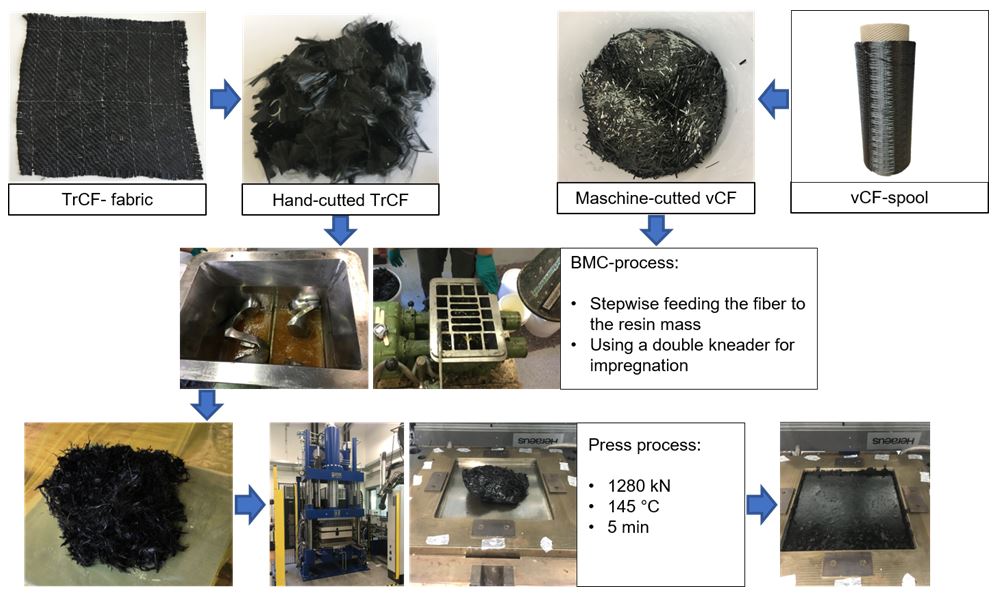

The Fraunhofer Project Center Wolfsburg focuses on the use of renewable resources such as wood, natural fibers and biopolymers and their combination, the development of recyclable products and the elaboration of reuse concepts for fiber-reinforced EoL components.

Possible scenarios for EoL are already considered during material and product development. These include repetitive use, possibilities for separation by type as well as ecological and economic sensible recycling options. Finally, life cycle assessments are performed for the developed materials, products and processes in order to demonstrate the advantages compared to conventional products and processes.

Fraunhofer Project Center Wolfsburg

Fraunhofer Project Center Wolfsburg